3. The harvesting of the olive

The process of olive harvesting is something that is carried out in a

manual in this area and that is transmitted from generation to generation.

The duration of the campaign depends on the number of olive trees

to collect and the type of olive and olive, usually lasts about 4 months

They vary from November to the end of March or April. (In Malaga)

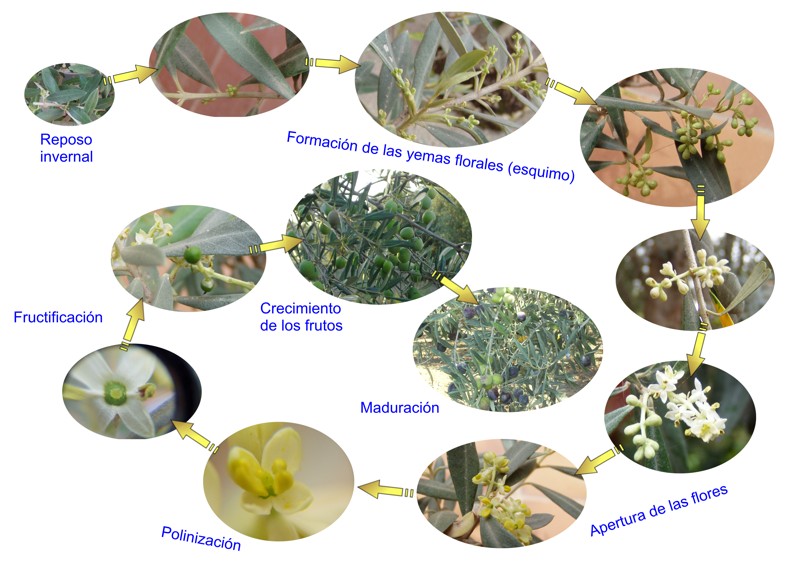

The growth process

To make the collection, we start by placing canvases (resistant and large canvas)

with a rectangular shape) on the ground, just below the olive tree that we are going to collect, avoiding

Olives fall directly to the ground and it is easier to pick them up and take advantage of them all.

Once placed, so that they fall from the olive tree, they are beaten with a special stick, giving directly to the branches. This part of the process needs a very perfected technique, because if it is not done correctly we can damage the tree, reducing future production and damaging the crop.

Once the olives are in the canvas, they are piled up, and later, when they are all collected, remove the leaves and the smaller stems that have fallen from the tree.

After being cleaned, they are put inside pita sacks (we speak of sacks made with yarn obtained through agave fibers) and they are taken to the mill, where they are milled and the olive oil is made. This process is repeated with each olive tree until all the olives are picked.

Oil production in a cooperative:

It is common to work as a team when making oil since the necessary machinery requires a large investment, farmers create cooperatives in which they associate to produce and sell the oil in an advantageous way for all.

In this way they take their olives here once they are collected and there the oil is manufactured and then sold under the same name, which represents all the members.

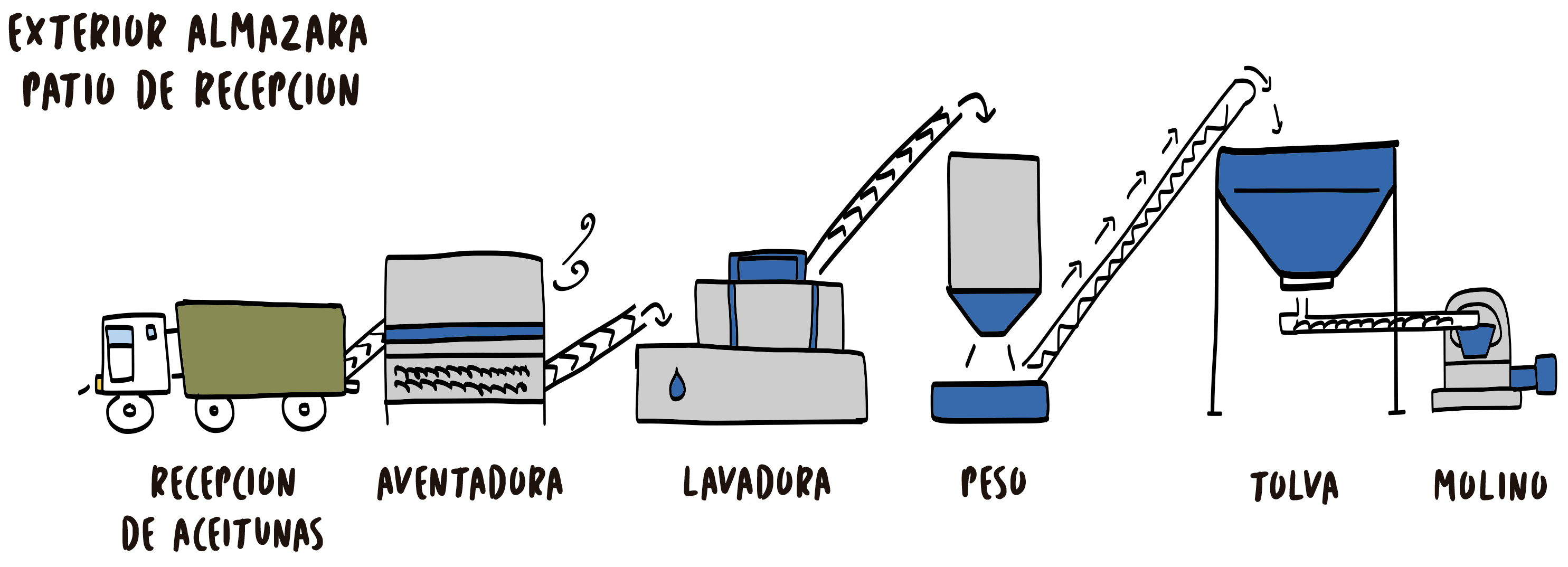

In the cooperative they are poured into a hopper (a container in the shape of a pyramid or inverted cone, which allows the slow passage of the olives to another container with a narrow mouth through an opening in the bottom) that stores them until a ribbon transports them towards an aventadora that removes the leaves and the stems that have remained.

Later it passes to a washing machine that washes the olives and removes the stones. A mechanical tape transports them and they are weighed to know the amount of clean olive that each farmer contributes and stored again in hoppers, until the time they are taken to the mill to make the oil.

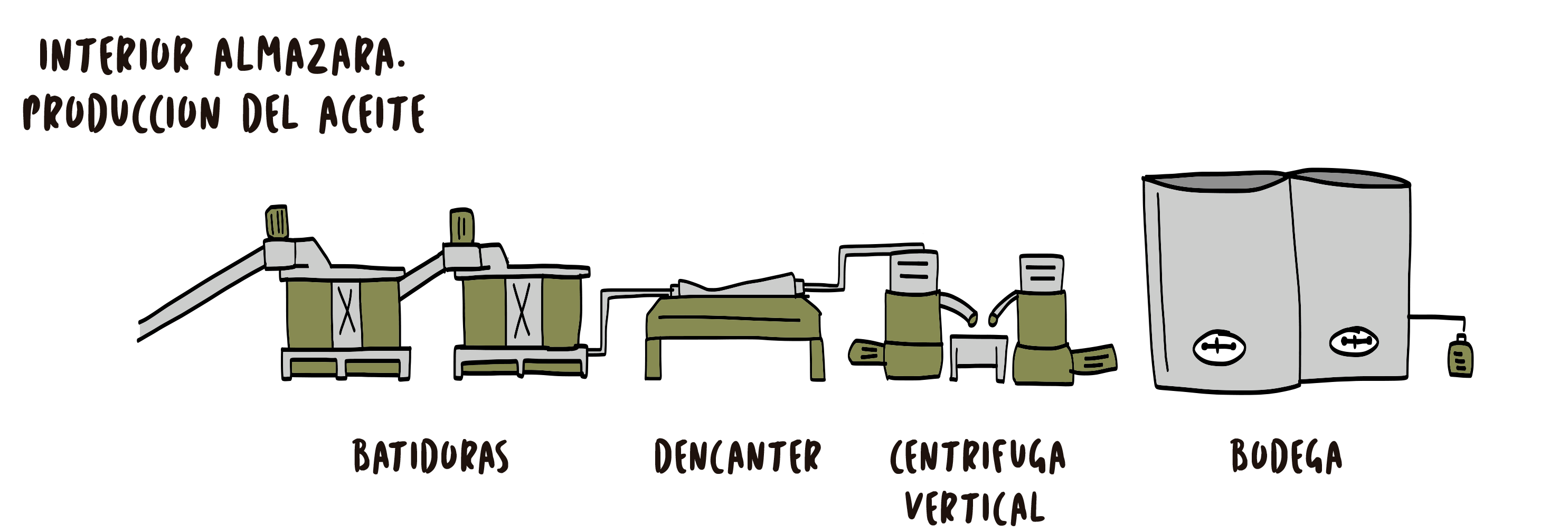

In the mill, they crush the olives, which can lead to the formation of emulsions between oil and water. Therefore, it is necessary to make a paste shake to increase the size of the oil drops.

This process is carried out in the thermo-blender at temperatures slightly higher than the ambient one and its duration, in no case, must be less than one hour. Once it is shaken, the oil is separated from the groundmass (pulp + vegetation water) due to the centrifugal force that increases the differences between the specific densities of the oil and the “alperujo” (solid matter plus vegetation water). This operation is carried out in a horizontal centrifugal decanter.

After this, the oil is subjected to centrifugation in a dish centrifuge where a certain amount of water is added to the oil in order to wash it and be able to remove part of the moisture that it bought from the decanter, with water being the only residue that is eliminated in This process of oil extraction.

When the oil leaves the plate centrifuge it is ready for storage, which is made in waterproof tanks, which allow the oil to be kept hermetically and that does not absorb any smell or taste, as well as maintaining an average temperature of 17º C that prevents its freezing.